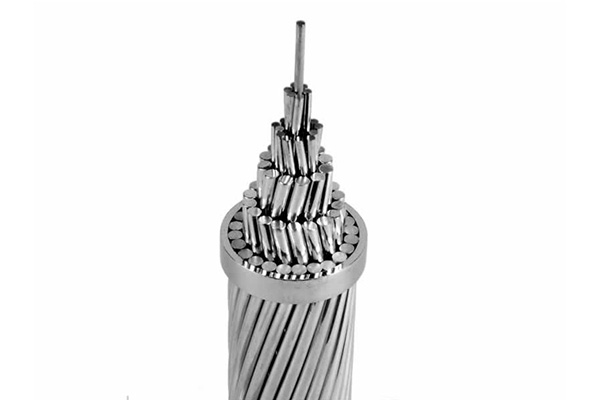

All Aluminum Alloy Conductor (AAAC Conductor)

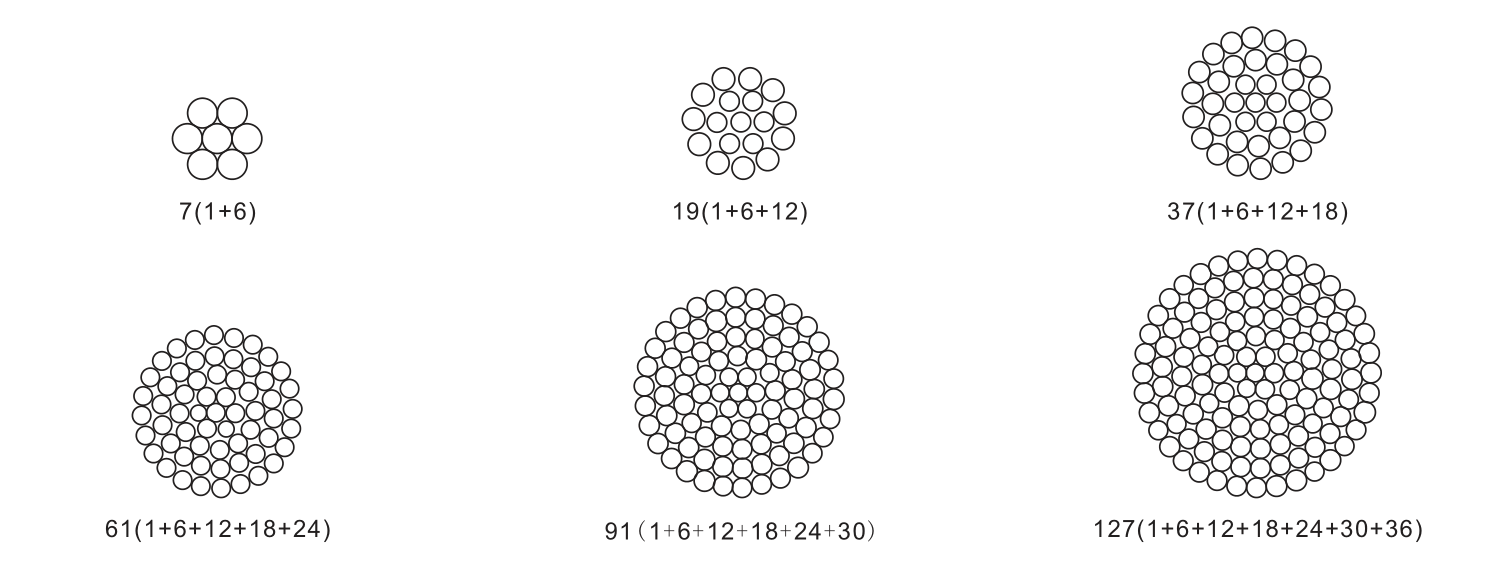

Aluminum alloy stranded wire, aslo know as aaac sorbus conductor, is mainly used for long-distance overhead lines, but also can be used as overhead line bearing line or other cable core. Mainly ASTM B399 standard, BS EN50183 standard, BS3242 standard, IEC61089 standard, French standard, DIN standard and other manufacturing standards. Our company can provide high strength aaac wire, heat resistant aluminum alloy wire, gap type wire, medium strength aluminum alloy wire and aluminum alloy core aluminum strand and other products.