All Aluminum Conductor Advantages

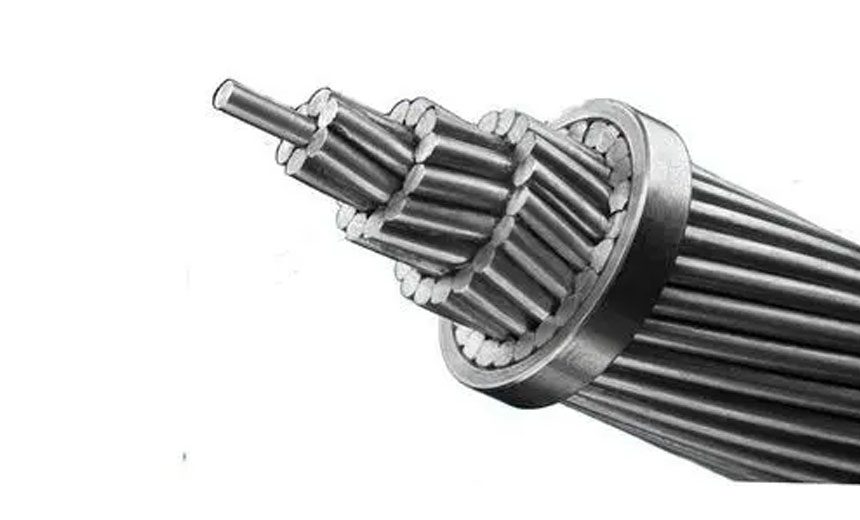

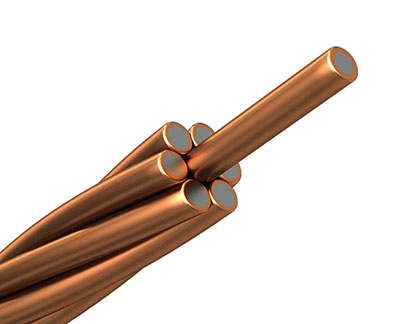

All Aluminium Conductor (AAC) is a type of cable that is becoming increasingly popular due to its many advantages over other forms of cable. This aac cable offers superior electrical conductivity, a lightweight design, and resistance to corrosion. The aac all aluminum conductor is also easy to transport and install, as it is extremely flexible and can be used in a variety of applications. Furthermore, aac all aluminum conductor is much more cost-effective than many other options, making it an attractive choice for many projects.

How to Store an All Aluminium Conductor?

Storing an All Aluminium Conductor (AAC) cable is a simple and straightforward process. This aac cable should be stored indoors in a dry, well-ventilated area with a temperature of 0°C to 40°C and humidity of 30-75%. The aac all aluminum conductor should be separated from combustible materials, and stored on wooden pallets or skids. Make sure to protect the cable from direct sunlight, moisture, and any other materials that may cause corrosion or damage. Be sure to inspect the cable for any signs of damage before use.

How to Choose All Aluminium Conductor?

Choosing the right all aluminium conductor (AAC) cable is important for safety and performance. When selecting an AAC Conductor, you should consider its conductor size, voltage rating, and temperature resistance. The AAC all aluminum conductor has high conductivity, making it a better choice than other types of cables. Furthermore, aac aluminum conductors are lightweight, durable, and can be used in a variety of applications. When selecting an bare overhead AAC conductor, it is important to ensure that it meets the required safety standards. Additionally, checking the manufacturer's warranty will ensure that you get a quality product.

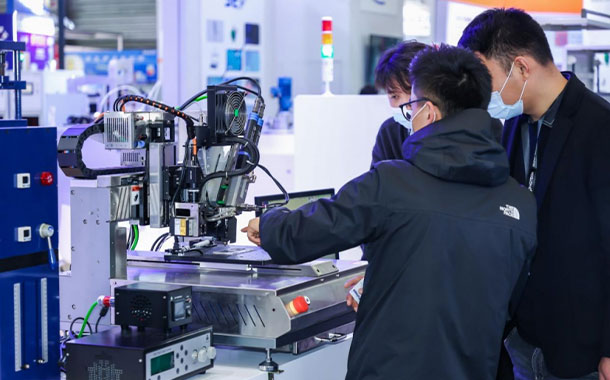

All Aluminium Conductor Manufacturing Process

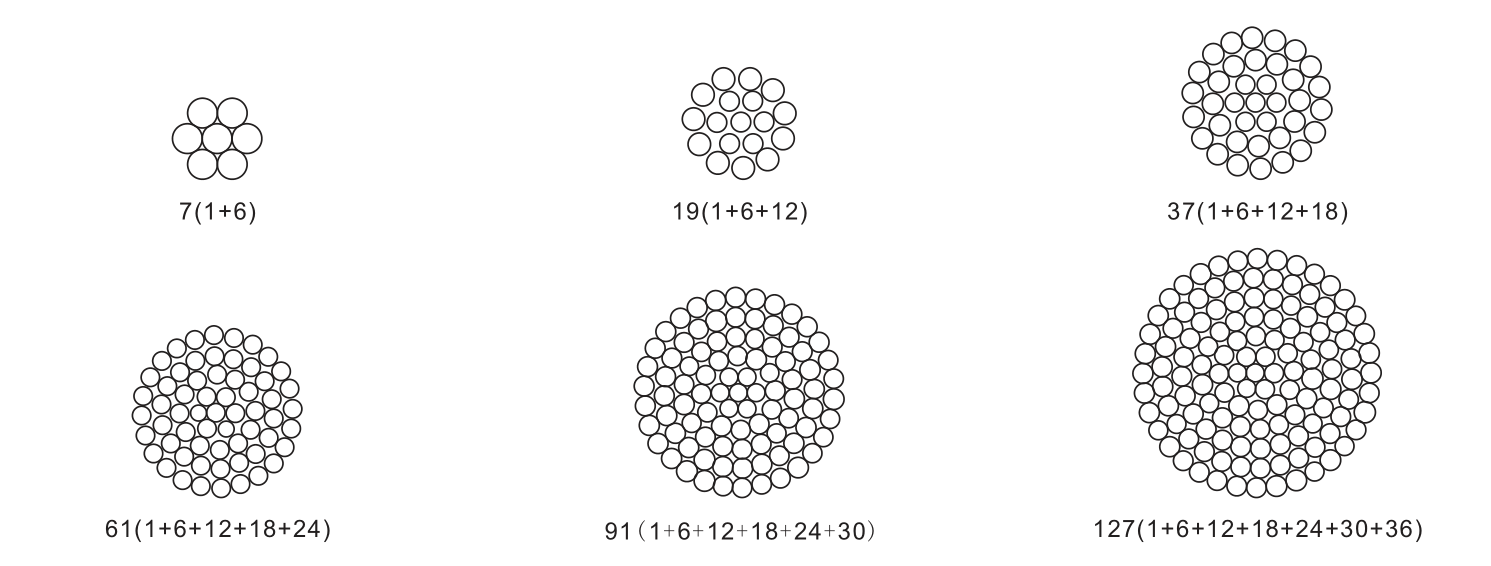

The all aluminium conductor (AAC) is made of aluminum strands and is used in low and medium voltage power lines. The manufacturing process begins with molten aluminum which is poured into a cylindrical steel mold and cooled. After cooling, the conductor is cut into the desired size and shape, that's electrical round aluminum rod. It can be φ12mm or φ9.5mm aluminum rod, but the mild tensile strength should be different to ensure that the tensile strength uniformity of the drawn aluminum single wire does not exceed 20MPa. When producing stranded aluminum wire, it is necessary to pull the φ9.5mm aluminum rod into aluminum wire with smaller diameter, such as 2.1mm, 2.15mm, 3.0mm, etc., and then strands of aluminum wire are twisted together to synthesize stranded aluminum wire. Finally, a protective coating is applied to the aac all aluminum conductor to protect it from environmental conditions. This process results in a lightweight and durable conductor that is ideal for use in overhead power lines.